Forming Services

At Smucker Laser Cutting and Metal Fabrication, we take pride in our expertise in metal fabrication, offering a comprehensive range of services to meet the diverse needs of industries such as architecture, building, HVAC, electronics, and semiconductors. Our forming services are at the core of our fabrication capabilities, enabling us to transform various materials. We specialize in manufacturing sheet metal fabrications from steel, aluminum, stainless steel, and copper into custom components with precision and efficiency.

What is Forming?

Forming is a critical metalworking process that shapes metal sheets into various configurations using force, pressure, or heat. Essential in metal fabrication, forming allows for the creation of custom components with precise dimensions and geometries. At Smucker Laser Cutting and Metal Fabrication, our forming services encompass a range of techniques, including bending and shaping, tailored to meet the unique requirements of our clients.

Our Forming Process

Press Brake Equipment:

Our Safan press brake utilizes up to 220 US Tons of force, forming the cornerstone of our forming capabilities. This advanced machinery allows us to handle materials longer than 13′, ensuring precise bends according to your specifications.

CNC Precision Bending:

We also utilize the RAS TURBObend CNC machine, capable of processing materials up to 14 ga in thickness and 10′ in length. This machine enhances our bending capabilities, providing versatility and accuracy for a wide range of applications. Smucker Laser Cutting and Metal Fabrication offers full bending capabilities for various shapes and sizes to the architectural, building, and electronic industries.

Forming Services at Smucker Laser Cutting + Metal Fabrication

At Smucker Laser Cutting and Metal Fabrication, our precision forming services leverage advanced equipment, material expertise, and a commitment to excellence to deliver custom metal components that exceed expectations. Specializing in metal forming, we cater to various industries, ensuring high-quality results for every project. Contact us today to discover how our precision forming services can elevate your metal fabrication projects to new levels of quality and precision.

Specifications

- Fabrication Methods

Bending

- Maximum Bending Thickness

Hot Rolled Steel, Cold Rolled Steel, Stainless Steel: 3/4″ Thick

Aluminum: 1/2″ Thick

Stainless Steel: 1/2″ Thick

- Tolerance

+/-0.001″

- Equipment List

RAS TURBObend CNC Bending Machine

Safan Press Brake

- Drawing Types Accepted

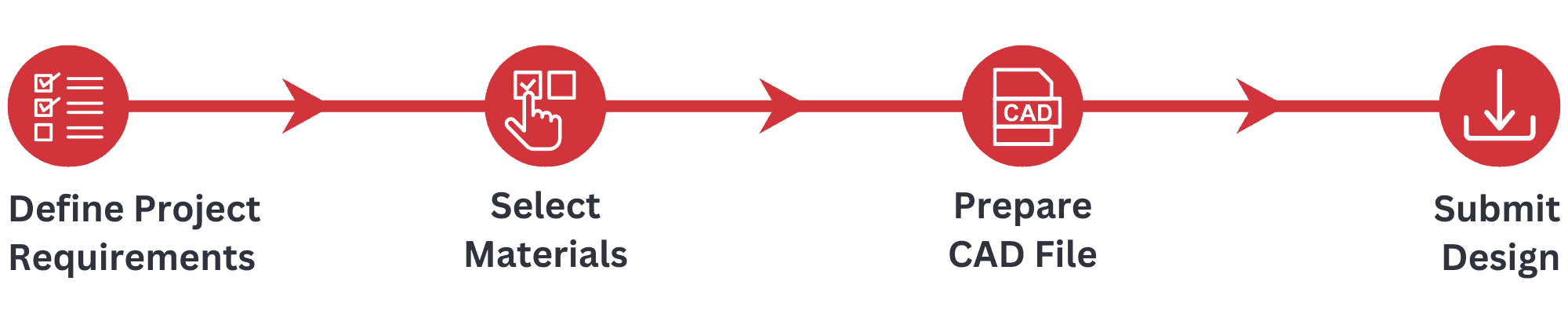

.dxf files preferred (all CAD accepted)

SolidWorks Files

Drawings

Blueprints

Sample pieces

Additional Services and Capabilities

- Production Focus

Large product geometry

Thin materials

- Industry Focus

Agriculture

Construction

Architectural

Aerospace

Automotive

Building

Electronic

Medical

Semiconductor